Choosing the right band saw blade

In order to correctly select the right band saw blade for your needs, there are several factors to be taken into consideration. We will describe the three types of band saw blades more in depth, according to the desired cut efficiency, the right dimensions of a blade and aspects regarding the hook angle, pitch and overall shape.

For starters, when choosing about your saw blade, we advise you to take into consideration the maximum cutting speed and the speed of the band saw blade (peripheral speed).

Depending on the desired wood cutting efficiency, we must choose between the following three types of blades:

Depending on the desired wood cutting efficiency, we must choose between the following three types of blades:

Set tooth blades - are easier to fabricate, and the initial investment is smaller. Moreover, they are easy to maintain.

Swage tooth blades - offer high cut efficiencies, but their maintenance in an expensive technology.

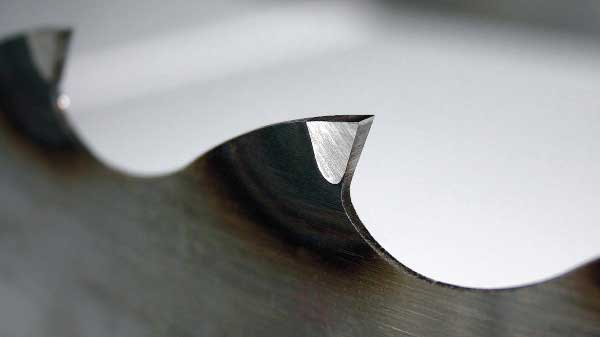

Stellite tooth blades - offer the highest cut efficiency, and because of this reason as well as from an economical point of view they are the best, especially due to the increased cutting speed and durability while cutting. On the other hand, the cut surfaces also have a higher quality.

Choosing the correct dimensions of the band saw blade depends only on the bandsaw.

The initial blade width, measured from the top of the tooth to the back of the blade, has to be equal to the width of the wheel plus the height of the tooth plus 3 mm, representing the gap between the bottom of the gullet and the edge of the wheel. The thickness of the blade is chosen based on the diameter of the wheel and it has to be approximately 1/1000 from the diameter of the wheel. The length of the blade is generally recommended by the machine producer; the generally recommended tooth space, the number of teeth and the minimum and maximum constructive lengths are given.

The saw tooth characteristics are very important in order for the cut to offer optimal results. The durability of the cutting edge, the cutting force and the feed speed are only a few of the characteristics that require attention. Regardless of the type of wood being cut, the gullet area has to be as big as possible for the elimination of sawdust to be efficient. For the soft wood it is generally recommended to use a bigger pitch, and for a harder wood a smaller pitch, in order for more teeth to be simultaneously engaged in the cut.

Therefore, the most important parameters when choosing the pitch and shape are:

The type of wood that is being cut

The diameter of the log or cutting height

The speed of the cut

Here you can find the tooth shapes available at Metamob, with the observation that any type of shape indicated by the client can be executed.

The hook angle has to be suitably selected to offer the necessary power during the cut. A big hook angle offers a more efficient cut, but can reduce the stability of the tooth during the cut. For cutting soft wood or large sized timber, it is recommended to use a 25°-30° angle for the swage and stellite-tipped blades and 10°-15° for the set teeth. Both a hook angle that that is too small or too big can cause many problems during the cutting process, including cracking, especially in the bottom of the gullet.

The PVi tooth shape, which helps in the efficient elimination of sawdust, is generally recommended for winter use. The variable pitch consists of a repeating sequence of unequal tooth spaces and it is recommended in many situations, including cutting during the winter season or especially hard wood. By using this type of pitch the vibrations can be reduced and it is an increase of the feed speed becomes possible. The variable depth refers to the unequal depths in the gap between two teeth. This also helps with reducing the vibrations. We can execute a vario pitch with a constant or variable height. Usually, a sequence has 4 or 6 teeth, and based on the desired effect, we can choose that the difference between the teeth to be bigger or smaller. Generally, automatic grinding machines are recommended for sharpening and maintaining blades with more complex features such as those mentioned above.

Further information about choosing a band saw blade can be offered by Metamob consultants during a technical assistance.

Contact

Adress: 440122, Satu Mare, Aurel Vlaicu 102-106, Romania

Phone: +40-261-711511

Email: metamob@metamob.ro