Levelling

Levelling is an operation that belongs to general blade maintenance, aiming the removal of local defects from the blade surface, such as concave or convex deformations. The size of these flatness deviations can exceed the setting amount, causing friction with the lateral sides of the cut.

The above described defects can hit the guides producing deviations of the blade on the fly-wheels. In most cases convex deformations appear on the outer sides of the blades because of the sawdust that reaches between blade and wheels.

The leveling operation is done first on the inner side of the blade and then on the outer one. Checking is done with a special ruler, on the length and width of the blade. The ruler is moved along the blade in a slightly inclined position, marking the defective areas. Checking is done in the same way on the width of the blade.

A light source behind the ruler will be of great help in tracking the convex deformations. Operators perform the leveling after all the areas with flatness deviations have been identified. This operation can be done by hand with a wedge shaped special hammer.

Levelling and tensioning operations are done after each cutting session, depending on the condition of the blades after checking. These two operations are very much related and therefore it is recommended to be performed together.

Levelling and tensioning operations are done after each cutting session, depending on the condition of the blades after checking. These two operations are very much related and therefore it is recommended to be performed together.

The levelling operation requires high labor costs and a lot of time. Therefore a rationally operating of the blades is much recommended. Automatic electronic control and repair machinery that can track and remove defective areas are also of great use.

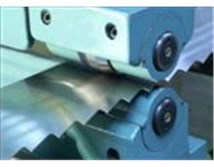

The contact sensors or no contact control samples measure the deformations on the entire length of the blade, on pre designed points (distances) indicating the flatness deviations, the convex or concave areas formed in the steel of the blade. Based on the measurements results, the pair of rolls tends to correct deviations. Tensioning is measured continuously until the value of deviations decreases under the chosen tolerance limit.

On automatic tensioning and leveling machines the computer program measures the tension on the entire width of the blade. The tensioning unit gets active and keeps this state until the required tensioning level is reached. Tensioning and levelling procedures can be programmed depending on the size of the blade and the required specific parameters.

Automatic machines perform all the programmed operations without human surveillance and stop according to these preset instructions.

Find out more about: Back line checking ruler

Contact

Adress: 440122, Satu Mare, Aurel Vlaicu 102-106, Romania

Phone: +40-261-711511

Email: metamob@metamob.ro